How Do You Sterilise and Clean Surgical Instruments?

Surgical instruments are used exclusively in sterile spaces, and they’re specifically designed to penetrate a patient’s skin or mucous membrane.

In this post we’ll discuss some best practice techniques for cleaning and sterilising surgical instruments.

Benefits of Effective Cleaning and Sterilisation of Surgical Instruments

Infection Prevention and Control

As such, cleaning and sterilising surgical instruments before use is an essential part of infection prevention and control in hospitals.

Prolong Surgical Instrument Lifespan

Effective cleaning and sterilisation can also prolong the lifespan of surgical instruments, keeping them as sharp and effective as possible for as long as possible.

Decrease Turnaround Time

And an efficient cleaning and sterilisation process can help streamline your entire department, helping to reduce the turnaround time between procedures.

The Difference Between Cleaning and Sterilisation

There is a difference between cleaning a surgical instrument, and sterilising a surgical instrument:

- Cleaning – Using water and disinfectant to remove organic matter.

- Sterilising – Using chemicals or specialist equipment to remove all microbes from an object.

A surgical instrument must be sterilised before use. But it must be visibly clean before it’s ready for sterilising.

How to Clean and Sterilise Surgical Instruments

Different instruments may go through different cleaning and sterilisation processes depending on their material, and their frequency of use. But this is the general process that the majority of instruments will go through between uses.

Step 1 – Preprocessing

Following a surgical procedure, surgical instruments are treated with transport gels at the point of use. These gels prevent the drying of bioburden, which can make later cleaning and sterilisation processes faster and more effective.

Step 2 – Manual Cleaning

Once treated with transport gel, the sterile instruments are taken to a dedicated decontamination area. All instruments will then go through a manual cleaning process. Some instruments may have to be disassembled first, to ensure that all of their surfaces can be cleaned.

Ideally, the manual cleaning team will have access to a three bay sink:

- Bay 1 – Pre-rinsing instruments with cold water to remove transport gel, and organic matter such as blood and bone.

- Bay 2 – Immersing instruments in a solution, which will be either neutral detergent or enzymatic depending on the instrument. Following immersion, the instruments are brushed by hand.

- Bay 3 – Final rinsing. Depending on the instrument, manufacturers may recommend different treatments for the rinse water. If the water’s too hard, it can lead to spotting. Chloride levels can also damage instruments, and microorganism levels can lead to cross-contamination.

Step 3 – Automated Washing

Following the manual cleaning, surgical instruments will go through a specialist automated washing process. This is the sterilisation stage, where any microorganisms will be removed and killed.

Different instruments will require different equipment and processes, including:

- Disinfectors – The instruments are sprayed with pressurised water at a predefined temperature, flow, and chemical concentration. Manufacturers will recommend the optimum parameters for each instrument.

- Ultrasonic Cleaning – Some surgical instruments have delicate, hard-to-reach features including hinges and crevices. Automatic disinfector machines may not effectively clean these areas, so ultrasonic cleaning processes are used instead. This involves using high-frequency sonic waves to clean the entire surface of an instrument, often alongside low-foaming enzymatic cleaning agents. Instruments must be thoroughly washed with soft water following ultrasonic cleaning.

Step 4 – Storage

Following the cleaning process, surgical instruments are labelled to indicate the date they were cleaned. They are then carefully transported to, and stored within, a sterile environment until they’re ready for use again.

Essential Tips For Caring For Your Surgical Instruments

You’ll find many guides on our site to help you keep your surgical instruments sterile and in good working order for as long as possible:

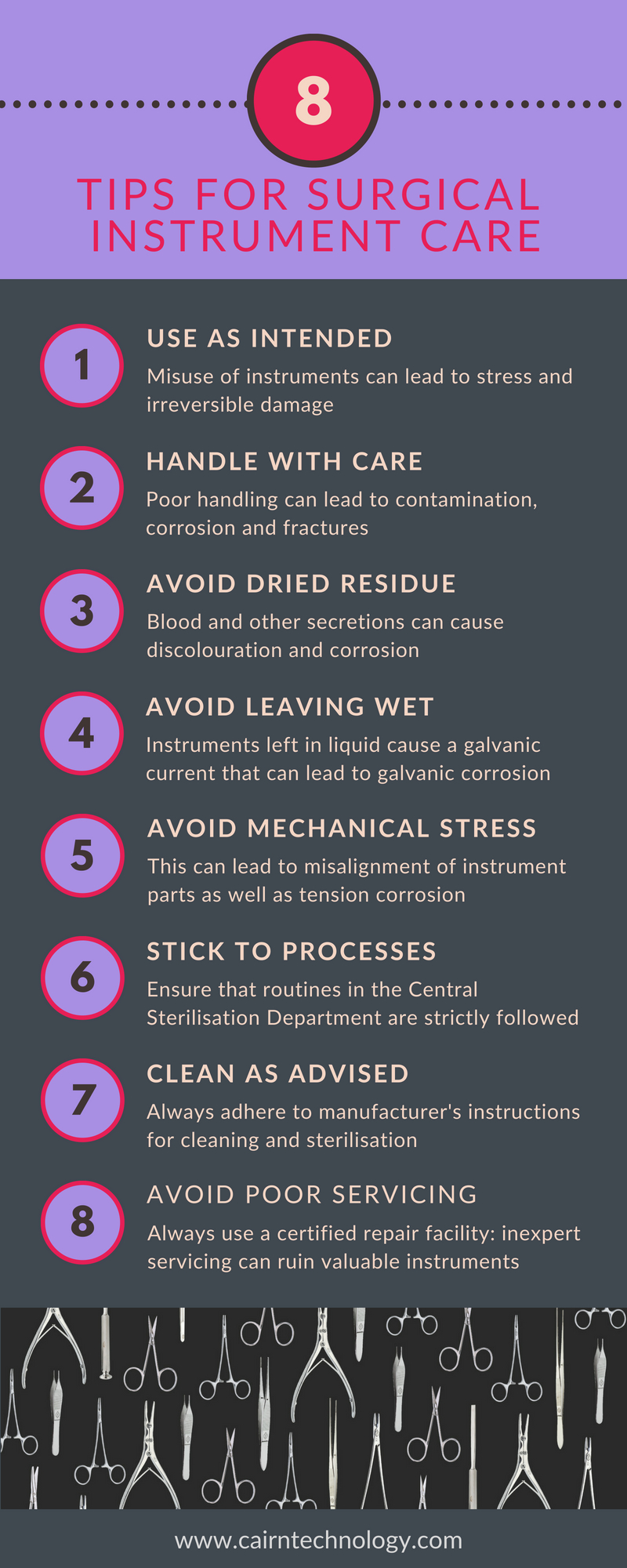

- 8 useful tips for surgical instrument care.

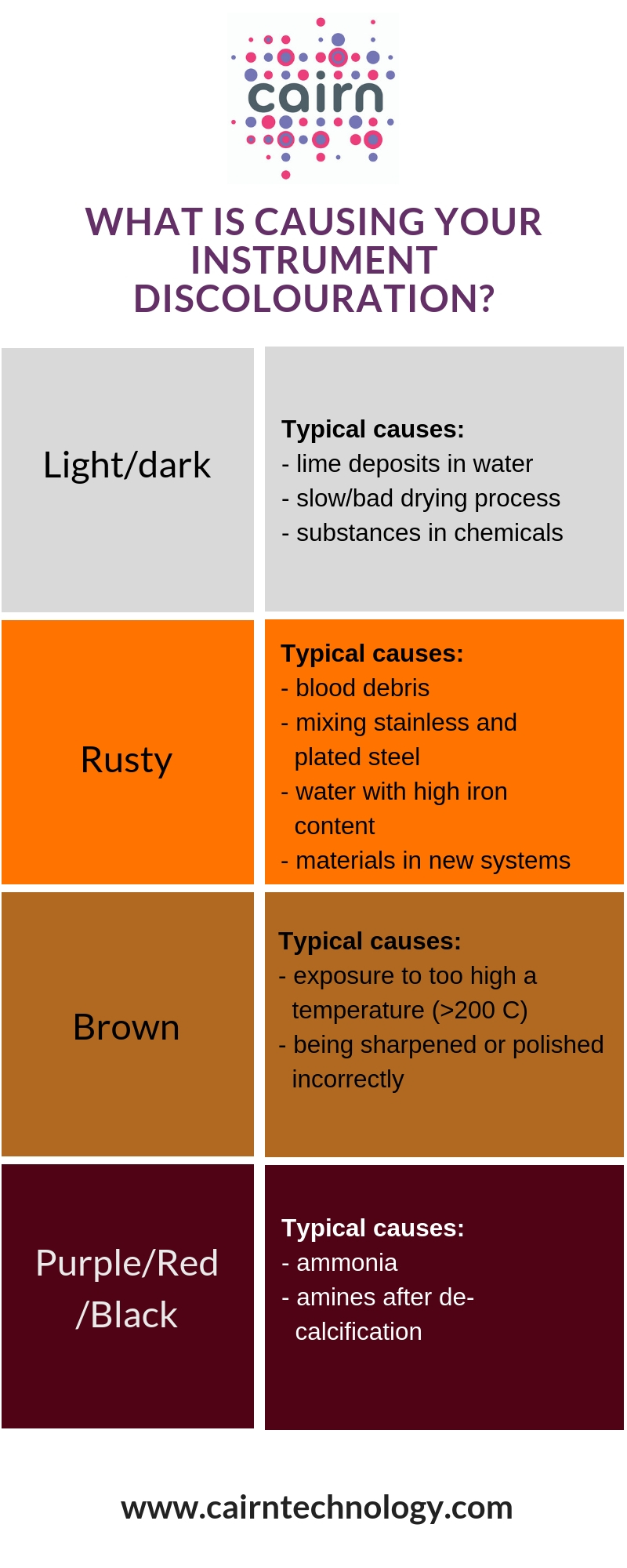

- Surgical instrument discolouration guide.

- An introduction to effective care and protection of surgical instruments.

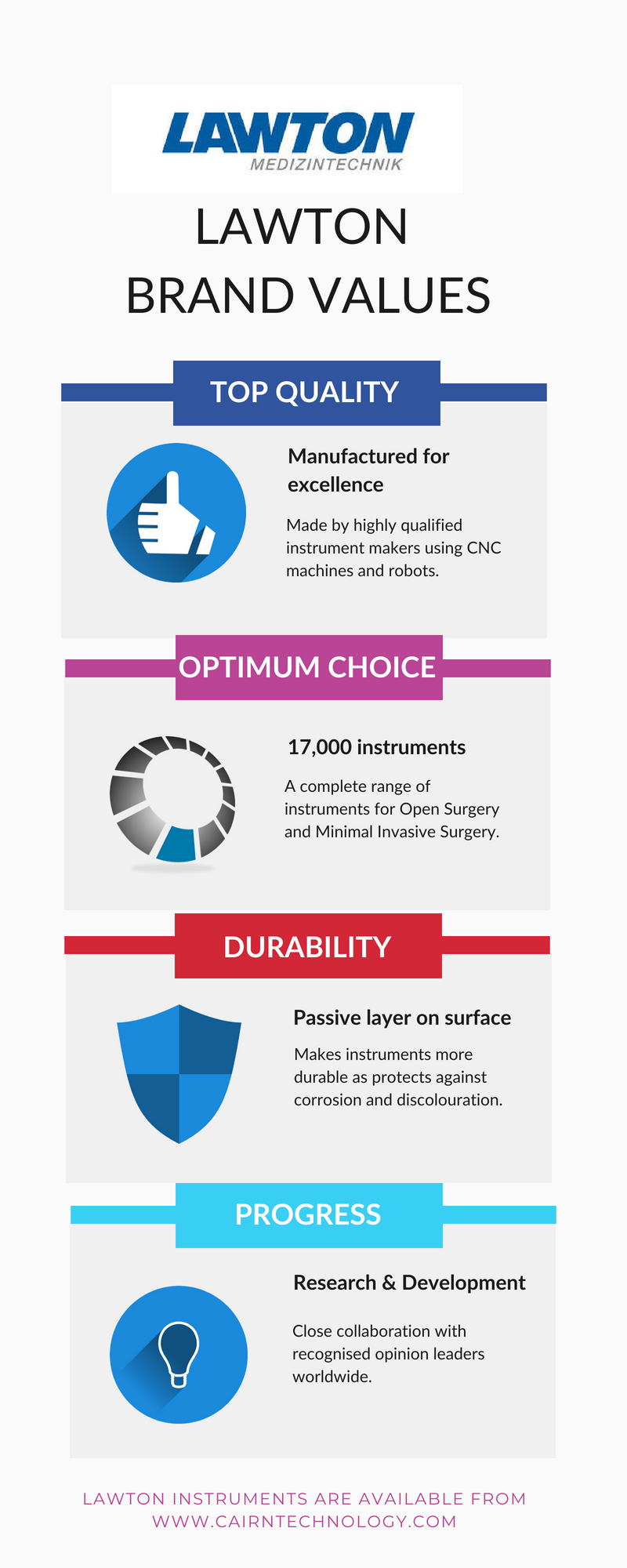

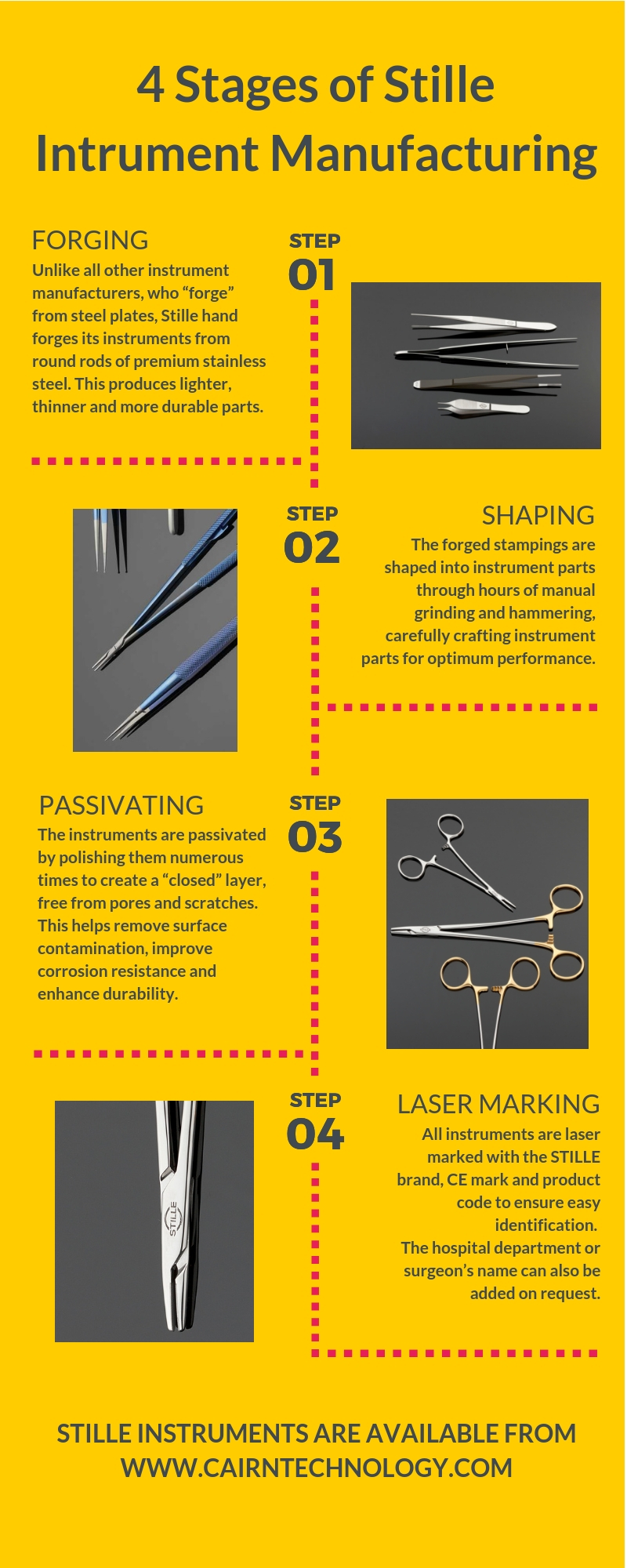

We also specialise in supplying high quality instruments for use across a broad range of surgical disciplines. If you’d like to discuss your surgical instrument requirements, get in touch to talk to an expert today.